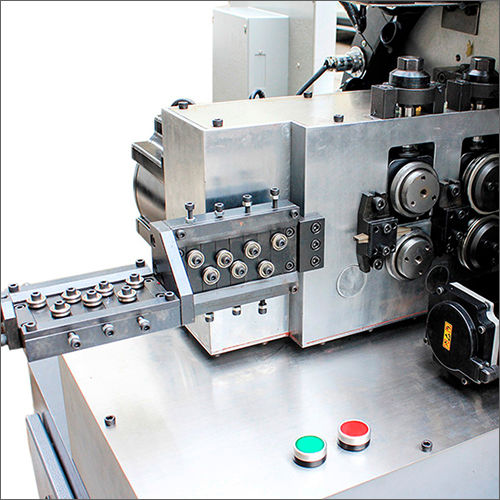

3-12 Axis Camless CNC Spring Forming Machine

Price 1600000 INR/ Unit

3-12 Axis Camless CNC Spring Forming Machine Specification

- Product Type

- Camless Spring Machine

- General Use

- Industrial

- Computerized

- No

- Automatic

- Yes

- PLC Control

- Yes

- Power Source

- Electric

- Voltage

- 220-440 Volt (v)

- Feature

- High Speed

- Warranty

- 1 Year

3-12 Axis Camless CNC Spring Forming Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About 3-12 Axis Camless CNC Spring Forming Machine

3-12 Axis Camless CNC Spring Forming Machine is suitable for making compression spring, tower shaped compression spring and flat wire spring. At our vendors end, it is manufactures by using high quality raw materials and components as per the set industry standards. Due to awesome features, longer function life and excellent performance, it is widely appreciated by our customers. Moreover, this 3-12 Axis Camless CNC Spring Forming Machine can be acquired form us in different specifications at market leading prices.

Specification

|

Brand |

YLSK |

|

Voltage |

380 V |

|

Frequency |

50 Hz |

|

Power Source |

Electric |

|

Dimension |

1400x850x1600 mm |

|

Model Name/Number |

YLSK-1020 |

|

Weight |

850 Kg |

|

Phase |

Three Phase |

|

Servo motor of Coiling Spinner (optional) |

0.4 Kw |

|

Servo motor of Quill (Z-axis) |

0.75 kw |

|

Servo Motor of Slide |

8x0.4 Kw |

|

Servo Motor of Wire Feed |

2.7 Kw |

|

Program Storage |

999 Max |

|

Axis Count |

3-12 Axis |

Advanced Camless Spring Forming Technology

This CNC Spring Forming Machine utilizes a camless design and sophisticated PLC control to manufacture springs with exceptional accuracy. Its versatile axis range, from 3 to 12, allows it to handle complex spring shapes and meet diverse industrial requirements, while the high-speed operation ensures efficient production.

Reliability and Ease for Industrial Users

Engineered for robust industrial applications, the machine's automatic functions and user-friendly interface make it an essential tool for manufacturers seeking to boost productivity. The built-in PLC control system and electric power source ensure smooth operation and easy integration into factory workflows.

FAQ's of 3-12 Axis Camless CNC Spring Forming Machine:

Q: How does the camless CNC spring forming machine operate without computerized controls?

A: This spring forming machine uses a Programmable Logic Controller (PLC) instead of a computer, automating all functions for efficient spring production. It is designed for fully automatic operation, streamlining the forming process using programmable mechanical instructions.Q: What types of springs can be produced using this 3-12 axis machine?

A: The machine is capable of manufacturing a wide variety of springs, including compression, tension, and torsion springs. Its flexible 3-12 axis design allows for the precise forming of both simple and complex spring geometries to meet various industrial needs.Q: When is it advisable to use a camless CNC spring forming machine in manufacturing?

A: This equipment is most beneficial for high-volume, precision-oriented spring production. It's suitable when consistent quality, speed, and reduced changeover times are required in industrial environments.Q: Where is this machine commonly used in India?

A: The 3-12 Axis Camless CNC Spring Forming Machine is widely adopted by factories, manufacturing plants, and workshops involved in the large-scale production of springs for automotive, electronics, and general industrial use across India.Q: What is the process for forming springs with this automatic PLC-controlled machine?

A: The operator programs the machine via its PLC system, setting parameters for spring shape and size. Raw coil wire is fed into the machine, where multiple axes and forming tools shape the wire according to programmed specifications, producing finished springs automatically.Q: What are the main benefits of using an automatic camless CNC spring forming machine?

A: Key benefits include increased production speed, improved product quality, reduced manual intervention, and the capability to form complex springs with high precision. The camless, PLC-controlled design also reduces maintenance and setup times.Q: How can dealers, exporters, and suppliers in India benefit from offering this machine?

A: Offering this advanced spring forming machine allows businesses to cater to customers seeking high-speed and precision manufacturing solutions, expanding their market reach and establishing a reputation for supplying state-of-the-art industrial equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Spring Forming Machine Category

5.5 Wire Feed Universal Camless CNC Spring Forming Machine

Price 2100000 INR / Unit

Minimum Order Quantity : 1 , , Unit

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : Camless Spring Machine

Power Source : Electric

CNC Spring Forming Machine

Price 3200000 INR / Unit

Minimum Order Quantity : 1 , , Unit

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : Spring Machine

Power Source : Electric

Universal Camless CNC Spring Forming Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : Camless Spring Machine

Power Source : Electric

CNC Spring Forming Machine

Price 2700000 INR / Unit

Minimum Order Quantity : 1 , , Unit

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : Spring Forming Machine

Power Source : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS