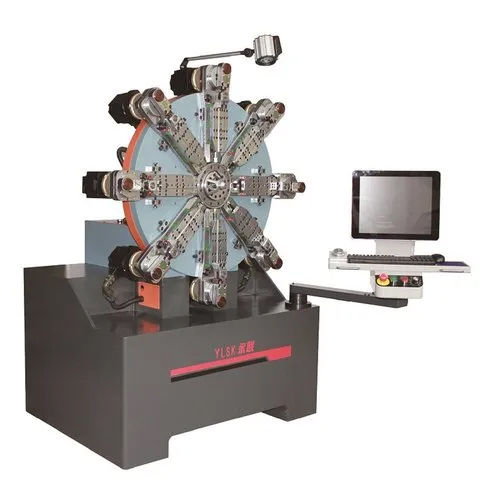

CNC Spring Forming Machine

Price 4000001 INR/ Unit

CNC Spring Forming Machine Specification

- Product Type

- YLSK-840RW CNC Spring Forming Machine

- General Use

- Industrial

- Material

- Other

- Weight (kg)

- 3500 Kilograms (kg)

- Automatic

- Yes

- Power Source

- Electric

- Voltage

- 380 V Volt (v)

- Warranty

- Yes

CNC Spring Forming Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 4-5 Days

About CNC Spring Forming Machine

| Automation Grade | Automatic |

| Brand | YLSK |

| Voltage | 380 V |

| Frequency | 50 Hz |

| Power Source | Electric |

| Weight | 3500 Kg |

| Phase | 3 Phase |

| Program Storage | 2000 Max |

| Servo Motor of Cam | 5.5 Kw |

| Servo Motor of Wire Rotation | 4.4 |

| Machine Size | 1500x2350x1900 mm |

| Servo Motor of Z-Axis Servo | 1 Kw |

| Axis Count | 4 Axis |

| Servo Motor of Wire Feed | 5.5 Kw |

| Model | YLSK-840RW |

| Servo Motor of Coiling Spinner (Optional) | 1 |

Precision and Efficiency in Spring Production

With CNC technology at its core, this Spring Forming Machine provides unmatched precision and consistency in crafting springs for industrial use. The automatic operation minimizes manual intervention, thus reducing error rates and boosting operational productivity. Its electric power source ensures stable and reliable performance, delivering high-quality springs to meet the most demanding requirements.

Robust Construction for Industrial Application

Built to international standards, the machine's 3500 kg structure ensures longevity and steadfast performance. Its compatibility with a 380 V power supply allows seamless integration into established industrial electricity networks, making it a trusted asset for long-term operations.

FAQ's of CNC Spring Forming Machine:

Q: How does the CNC Spring Forming Machine improve industrial spring production?

A: This machine leverages computer numerical control (CNC) for precise shaping and forming of springs. It automates the entire process, reducing manual labor, enhancing consistency, and significantly increasing production speed and quality for industrial applications.Q: What is the main benefit of choosing an electric, automatic spring forming machine?

A: Electric and automatic operation ensures uniform quality, energy efficiency, and ease of control. It allows businesses to scale production while minimizing downtime and maintenance, which is essential for industrial-scale manufacturing.Q: When should maintenance be performed on this machine?

A: Routine maintenance should be scheduled as recommended in the manufacturer's manual, typically after a defined number of operating hours or production cycles. Regular inspections help sustain peak performance and prevent unexpected failures.Q: Where can I purchase this CNC Spring Forming Machine in India?

A: You can buy the machine from authorized dealers, exporters, suppliers, and traders specializing in industrial machinery across India. Contacting established distributors ensures access to genuine products and reliable after-sales support.Q: What is the process for using this spring forming machine?

A: Simply connect the machine to a 380 V electric supply, configure the CNC program for your desired spring specifications, load material, and initiate the automatic process. The machine will form the springs as programmed, delivering consistent outputs.Q: What types of industries benefit most from this CNC Spring Forming Machine?

A: Industries involved in large-scale manufacturing of springs, such as automotive, electronics, machinery, and construction, gain significant advantages by utilizing this advanced equipment for streamlined, repeatable, and cost-effective production.Q: Does this machine come with a warranty?

A: Yes, the CNC Spring Forming Machine is supplied with a warranty, offering buyers peace of mind and ensuring reliable operation over the duration of the covered period.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Spring Forming Machine Category

3 Axis CNC Spring Forming Machine

Price 1700000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Power Source : Electric

Product Type : Spring Forming Machine

General Use : Industrial

Automatic : Yes

Universal Camless CNC Spring Forming Machine

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Product Type : Camless Spring Machine

General Use : Industrial

Automatic : Yes

CNC Spring Forming Machine

Price 2700000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Power Source : Electric

Product Type : Spring Forming Machine

General Use : Industrial

Automatic : Yes

CNC Camless Spring Forming Machine

Price 3500001 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electric

Product Type : YLSK1140 CNC Camless Spring Forming Machine

General Use : Industrial

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS