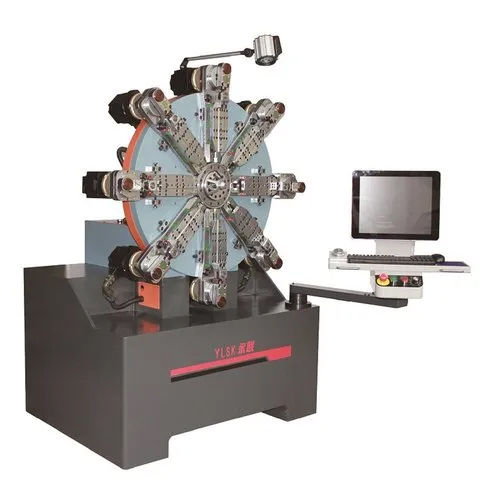

CNC Camless Spring Forming Machine

Price 6500001 INR/ Unit

CNC Camless Spring Forming Machine Specification

- Product Type

- YLSK-1250 CNC Camless Spring Forming Machine

- General Use

- Industrial

- Material

- Mild Steel

- Weight (kg)

- 3500 Kilograms (kg)

- Automatic

- Yes

- Power Source

- Electric

- Voltage

- 380 V Volt (v)

- Dimension (L*W*H)

- 2800x2200x2200 mm Millimeter (mm)

- Warranty

- Yes

CNC Camless Spring Forming Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 4-5 Days

About CNC Camless Spring Forming Machine

| Brand | YLSK |

| Voltage | 380 V |

| Frequency | 50-60 Hz |

| Power Source | Electric |

| Dimension | 2800x2200x2200 mm |

| Model Name/Number | YLSK-1250 |

| Weight | 3500 Kg |

| Phase | Three Phase |

| Servo Motor of Wire Rotation (Kw) | 2.7 Kw |

| Servo Motor of Cam (Kw) | 8x1.5 Kw |

| Servo Motor of Quill (Z-axis)(Kw) | 1.5 Kw |

| Program Storage | 999 Max |

| Servo Motor of Coiling Spinner (Optional) (Kw) | 1.2 Kw |

| Servo Motor of Wire Feed (Kw) | 5.5 Kw |

| Axis Count | 12 Axis |

| Machining Wire Diameter(Mm) | 1.2 -5.0 mm |

Advanced Camless CNC Technology

This spring forming machine utilizes a camless design controlled entirely by CNC systems, eliminating the complicated cam setup found in traditional machines. This results in faster changeovers between spring designs, more consistent production quality, and precise control of spring geometries, making it ideal for demanding industrial environments.

Industrial-Scale Durability and Reliability

Constructed from durable mild steel and weighing 3500 kg, this machine is built to withstand continuous, rigorous use in industrial settings. Its automatic functions reduce manual intervention, improve production speed, and help maintain uniformity across large volumes, making it an efficient investment for manufacturers.

FAQ's of CNC Camless Spring Forming Machine:

Q: How does a CNC camless spring forming machine operate?

A: This machine uses advanced CNC technology rather than mechanical cams to control the forming tools. The computer precisely directs each axis and tool, resulting in highly flexible and accurate spring production with quick design adjustments.Q: What are the main benefits of using a camless spring forming machine in industry?

A: Key benefits include rapid changeover between spring types, enhanced production speed, improved product consistency, and minimized downtime. Its automation reduces labor costs and enhances overall manufacturing efficiency.Q: When should I consider using this machine for my production needs?

A: You should consider this machine when producing diverse or complex spring designs, when demand volume is high, or when frequent design adjustments are needed. It's ideal for industries requiring precision and flexibility.Q: Where is this machine available for purchase in India?

A: The CNC camless spring forming machine is supplied by various authorized dealers, exporters, suppliers, and traders throughout India. It's advisable to source from reliable companies that provide warranty and after-sales support.Q: What is the typical process of forming springs with this machine?

A: The process involves feeding wire into the machine, where CNC-controlled tools shape it into the desired spring form. Programming is done via the control panel, allowing quick modifications and consistent spring formation.Q: How does the warranty support benefit the end user?

A: A warranty ensures that manufacturers have peace of mind regarding machine reliability. It covers potential defects or issues that may arise, reducing maintenance costs and production interruptions.Q: What materials can be processed with this CNC spring forming machine?

A: While this particular model is built from mild steel, it is capable of processing various spring wires compatible with industrial applications, depending on the specific configuration and requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Spring Forming Machine Category

Universal Camless Spring Forming Machine

Price 2100001.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Power Source : Electric

Product Type : YLSK1020 Universal Camless Spring Forming Machine

General Use : Industrial

4-12 Axis Universal Camless CNC Spring Forming Machine

Price 2700000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Power Source : Electric

Product Type : Camless Spring Machine

General Use : Industrial

CNC Camless Spring Forming Machine

Price 3500001 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Power Source : Electric

Product Type : YLSK1140 CNC Camless Spring Forming Machine

General Use : Industrial

CNC Spring Forming Machine

Price 2700000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Automatic : Yes

Power Source : Electric

Product Type : Spring Forming Machine

General Use : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS